Impressed by Japanese Kumiko woodworking, PC builder Nick Falzone made this beautiful wooden gaming PC with a customized hardline water-cooling system and a few beautiful craftsmanship. It’s known as Ikigai.

Because of our quickly rising PC constructing Fb web page, we’ve seen many customized gaming PCs, from mods primarily based on current case designs to scratch PC builds. You possibly can even submit yours for consideration proper right here. Right here we chat to Nick about how his gaming PC was constructed

: What impressed you to construct Ikigai – what have been your design influences and what look have been you making an attempt to realize?

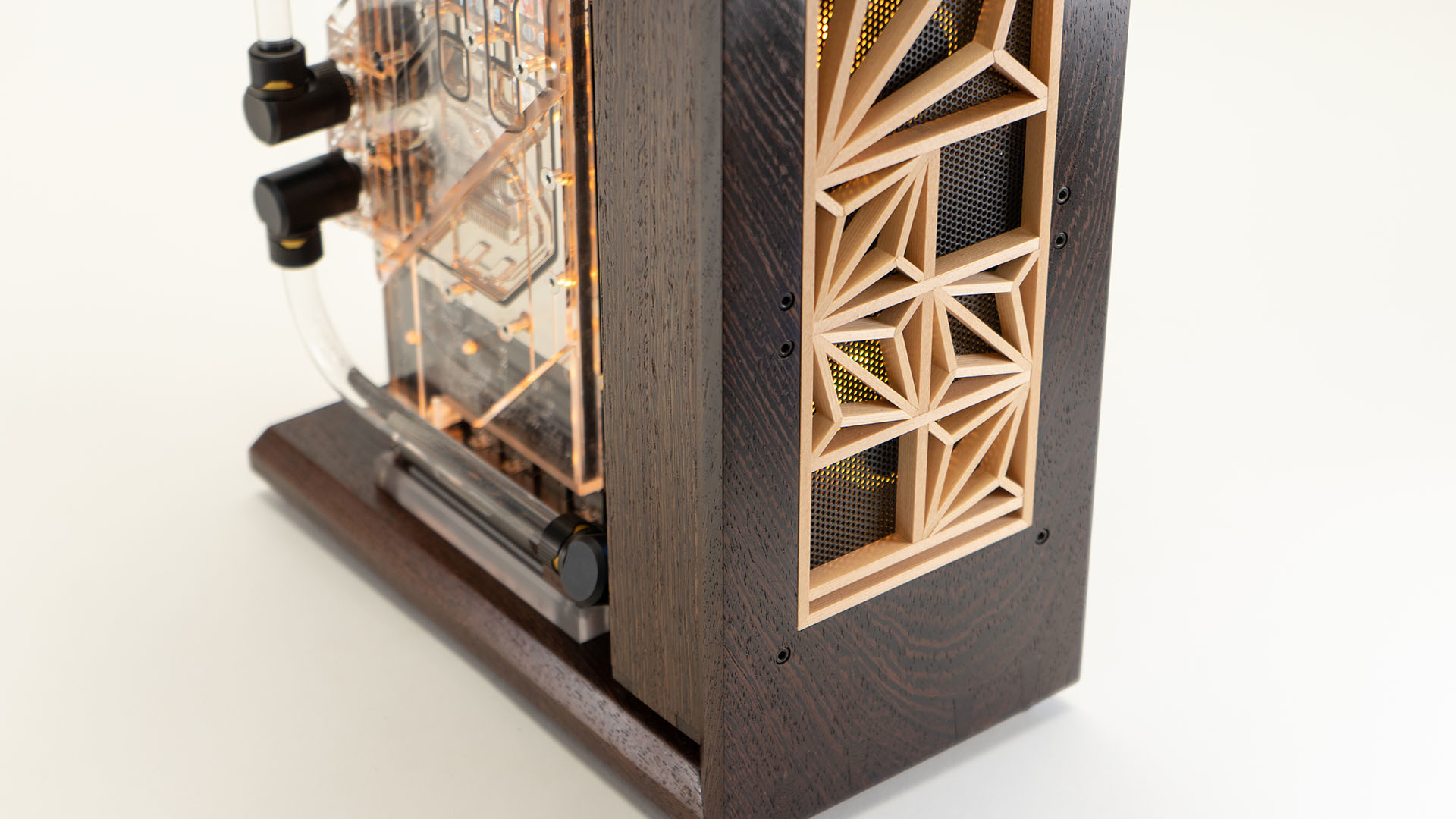

Nick: I wished to make a compact, scratch-built case with a clear look and a small desk footprint. As for the aesthetic, I actually wished to mix my love of Japanese woodworking and design with my new CNC machine’s capabilities. I actually wished to include Japanese Kumiko woodworking into the design and the wooden decisions have been primarily based on that call.

The wenge wooden that I used for the remainder of the case has a contemporary look that helped distinction with the light-colored Kumiko wooden. I additionally wished each facet of the case to have a objective, which helped hold the case and wiring as clear as attainable.

I selected the identify ‘Ikigai’ firstly as a result of I believed it sounded cool, plus most of my mods have Japanese names and I preferred how the kanji (written characters) appeared. The primary motive, although, was as a result of the time period ‘ikigai’ means to search out which means in a single’s life and, for the months that I labored on this mod, that is largely what I thought of and spent my time doing.

How did you go about planning and designing this construct?

I’m not superb at sketching, however I did a few tough sketches earlier than I took it to CAD. The Cooler Grasp Case Mod contest for which I made this case has dimension constraints (underneath 20 liters), so I actually needed to squeeze all of it right into a smallish envelope.

It seems I’m not nice at utilizing CAD both, so I made a number of full-scale fashions of the case out of low cost wooden to see how it might all match collectively in actual life. The case design modified so much with these fashions, as nothing appeared to prove in actual life because it did in cad. This course of additionally helped me work on the CNC G-code.

Inform us concerning the primary chassis. What supplies did you employ, and the way did reduce and form them?

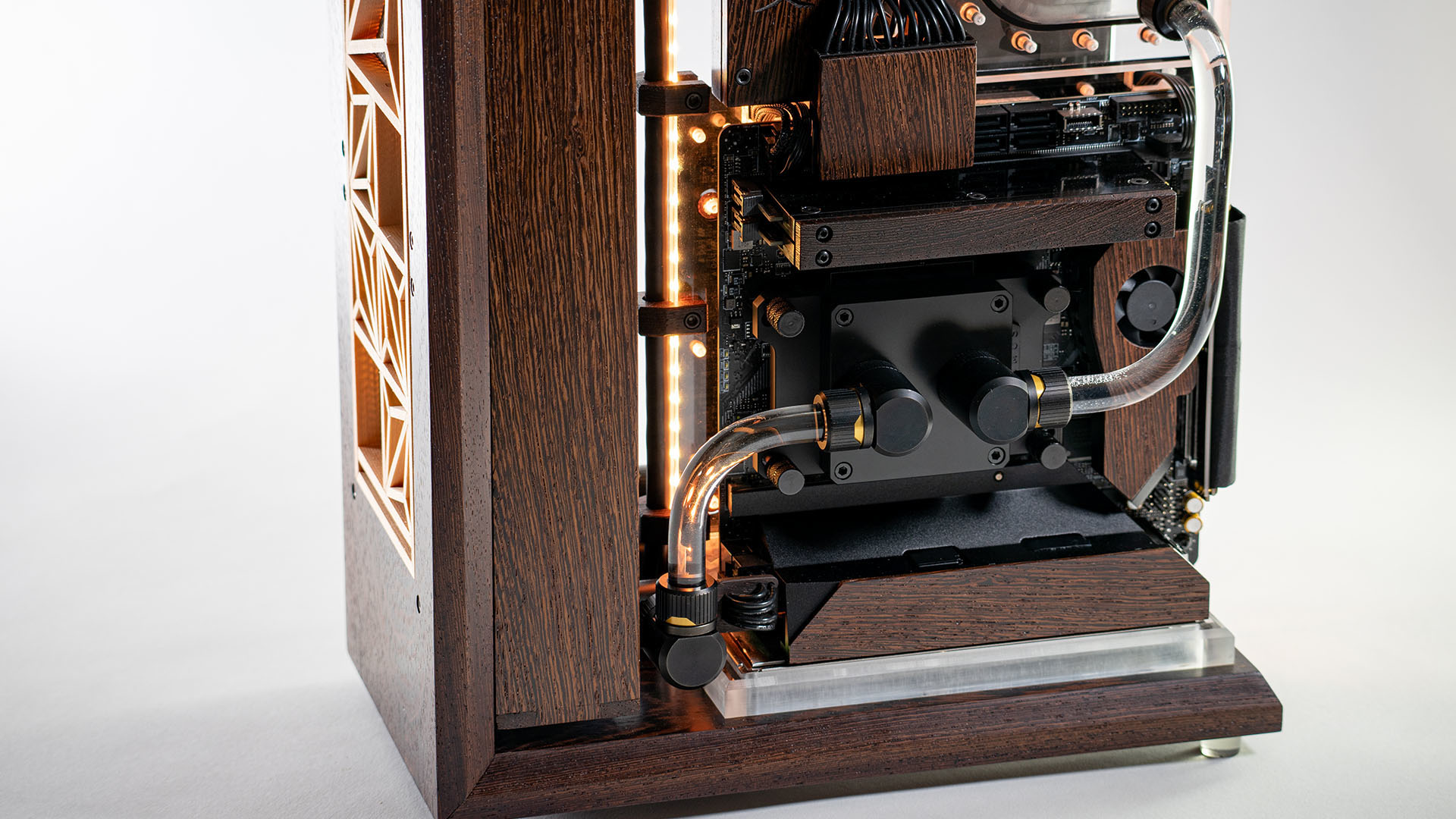

The case is a full scratch-build. A lot of the {hardware} is centered round a sandwich format, with a lot of the wiring within the heart panel of the case. The middle is made out of acrylic and incorporates a lot of the guts of the wiring and lighting, plus it had a distribution plate for the water-cooling system constructed into it. This piece alone took a very long time to get proper, as there have been many alternative components of it and I hadn’t made a distribution plate earlier than.

I made a number of check iterations out of wooden, which allowed me to verify for fitment, verify my G-code information and study the method I might use to make the ultimate product. The CNC mill does a variety of the work, however it nonetheless takes a variety of apply to anticipate any points that may crop up with the manufacturing of the plate, and to optimize the order of operations.

When it comes to format, I’ve the I/O plate on the underside. It is because I envisioned making a customized desk for this case, which could have a plate on the desktop to permit cables to be routed underneath the desk for a clear look. This additionally gave me the liberty to make the opposite sides of the case extra ornamental and according to the remainder of the case design.

That’s some superb element in entrance of the mesh on the entrance. How did you design the sample and reduce the wooden to form?

The sample itself is a standard Kumiko design that I’d wished to make for years and this appeared like an awesome alternative to make use of it. It’s primarily based on a grid, so I wished to play with the size of the ‘flower’ portion of the sample and use two totally different sizes of the principle ingredient. I made the design in CAD to verify I had the proportions proper and, as soon as this was shut sufficient, I milled up the wooden to a number of totally different thicknesses to make the Kumiko piece.

I used Sitka spruce for the wooden and left it unfinished. I began with the principle grid and reduce each bit by hand utilizing conventional hand instruments and strategies. With the principle grid achieved, I turned to the flower portion and made angled blocks, utilizing a hand aircraft to get constant angles on each bit. From there, I completed each bit and put them into place, utilizing only some drops of glue to maintain it collectively.

There are such a lot of wood particulars scattered across the energy connectors, heatsinks and so forth. Are these additionally produced from wooden?

These are all produced from scraps of the wooden used for the principle case. I wished each facet to tie into the case design all the way down to the smallest element. I made a lot of the items with my CNC machine, often making a few check items first. I made fashions of every piece in CAD, machined a check piece, checked that it labored after which made the ultimate piece out of the wenge wooden. It was time-consuming however the particulars assist convey all of it collectively.

Take us by the water-cooling loop – what components did you employ and the way does all of it hook up?

I used the distro plate to maintain the loop as neat as attainable, and since I didn’t have a ton of area with which to work. All of it begins on the pump mounted within the distro plate, which additionally acts as a small reservoir. It then heads to the CPU waterblock, then to the radiator, again round to the GPU block after which again into the distro plate and pump.

I used an Alphacool GPU block and radiator, EK fittings and an Optimus CPU block. It took a variety of mocking as much as get all of the components matched up cleanly with as few bends and fittings as attainable. This was additionally my first loop utilizing onerous plastic tubing, so getting the bends proper took a variety of apply.

I used EK PETG tubing with a 12mm outer diameter. I used a warmth gun and a few cheap types to do the bends, and I reduce the tubing with a PETG tubing shear and sanded the ends even and clean. Getting the lengths and angles proper was largely a technique of trial and error. I in all probability threw away as a lot tubing as I ultimately used.

How did you propose the lighting?

I used to be going to go no-RGB with this construct, since I didn’t wish to cope with routing all of the RGB cables, however for the reason that GPU block was going to have lights, I made a decision so as to add extra. The followers I used from Cooler Grasp even have lights and just one cable, in order that they have been simple to route.

There’s an RBG hub within the acrylic behind the graphics card, the place all of the lighting cables connect with go to the motherboard header. I used to be not sure if lighting the distro plate was doable, however I used a really cool and small strip of RGB lights from Alphacool and put them right into a slot within the plate to mild it up. The great thing about the RGB lighting is that I could make them no matter coloration I would like – I simply used orange for a lot of the images since I preferred the heat it added to the wooden.

The cable tidying is immaculate for an open-air construct – how did you cover all of the cables and route them so tidily?

The cable routing was an enormous deal for me, particularly with little room to cover extra cables. I began through the use of as few cables as attainable – there are solely two cables for the followers and their RGB lights, and solely two different RGB strips. The cables that got here with the Cooler Grasp energy provide have been already nice, and didn’t have cable sheathing on them, making them skinny already.

I used the 24-pin ATX cable because it got here out of the field, however I remade the remainder of the ability cables utilizing 16-gauge wire and customized cable combs. I used some area by the PSU to cover some cable slack, however there isn’t a lot since I reduce the cables to size. I stashed the remainder of the cables into the acrylic portion behind the graphics and subsequent to the motherboard’s 24-pin socket within the wenge cowl plate space. Among the cables took some inventive soldering to get sufficiently small to suit, however it all labored ultimately.

Did you come throughout any difficulties?

The toughest elements of the construct course of have been coping with the scale constraints and the period of time I needed to end the mod. I labored for about two months, virtually each day, together with nights after work, to get this case achieved by the competition deadline. That might have taken a toll on me had I not been so excited concerning the mission. The dimensions constraint points have been largely self-inflicted, however an additional centimeter right here and there would have made my life so much simpler.

I didn’t have a variety of particular difficulties – the toughest half was staying the course and dealing on the identical mission each day to get the case achieved in time. The planning within the earlier levels actually paid off so far as avoiding traumatic conditions with the construct manufacturing itself.

How lengthy did the construct course of take?

Going from idea to completed product took about 4 months, however a variety of this was planning and design time – the precise manufacturing time was fairly quick.

Are you proud of the tip end result, or do you would like you’d achieved a few of it in another way looking back?

I’m very happy with how this case turned out. With the period of time I took planning and designing each half all the way down to the smallest element, I used to be glad that the larger image of the case turned out to be cohesive too. I didn’t have a grasp drawing or render of how the case was going to look – it was largely only a design in my head, so it was a reduction after I made all of it work properly.

I’ve made a few modifications since I took the images. I’ve upgraded the Radeon RX 5700 card to a GeForce RTX 3080, which resulted in a brand new loop being made for the GPU facet, and new wiring for that facet as properly. The brand new card is so much smaller than the primary one, so becoming it took much more remodeling than I had deliberate. I additionally upgraded the 650W SX energy provide to the 850W model, however fortunately they use the identical cables. I upgraded the riser cable too, however in any other case the construct remains to be the way in which I made it initially.

I wouldn’t change a lot now, apart from making extra of a reservoir for the water-cooling loop. Getting the loop crammed takes fairly some time, and it received messy a few occasions. Additionally, the on/off change was an afterthought and I might have integrated it higher into the design.

Ikigai Kumiko wood PC specs

- CPU: AMD Ryzen 5 5600X

- GPU: MSI Radeon RX 5700

- Storage: 1TB WD Black SN750 SSD

- Reminiscence: 32GB G.Ability Ripjaws 3600MHz

- Motherboard: MSI B550I Gaming Edge WiFi

- PSU: Cooler Grasp 650W SFX

- Cooling: Alphacool GPU waterblock and radiator, Optimus CPU waterblock, EKWB fittings and tubing, Cooler Grasp SF360R followers

We’re blown away by the look of this wooden gaming PC, and we love the intricate Kumiko-style wood particulars on the entrance and sides – we bow all the way down to your woodworking abilities Nick!

This put up initially appeared on Customized PC, which has been overlaying superb setups for over 20 years and is now a part of . Be a part of our almost 500k member Fb group to debate this construct.

In case you contemplate your self to be an knowledgeable PC builder, you may submit your individual customized PC construct to us as we speak for an opportunity of being featured on sooner or later.